Soft Plastic film/flakes Single Screw Pelletizing line

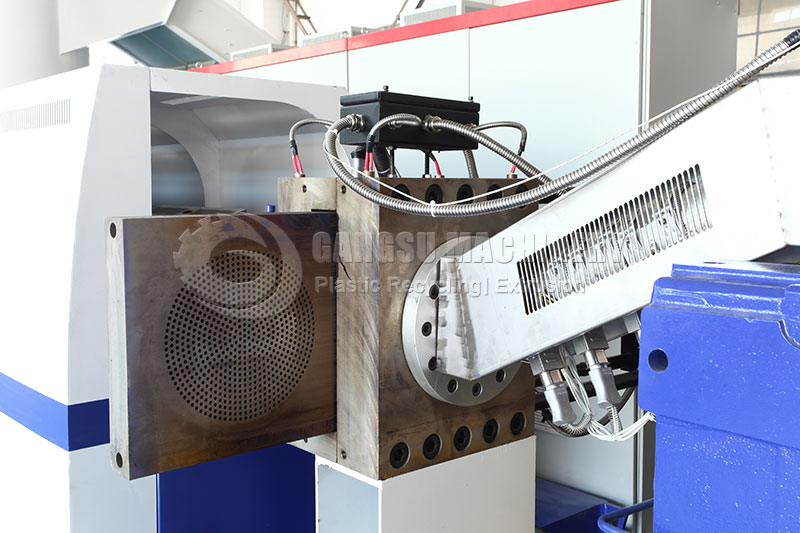

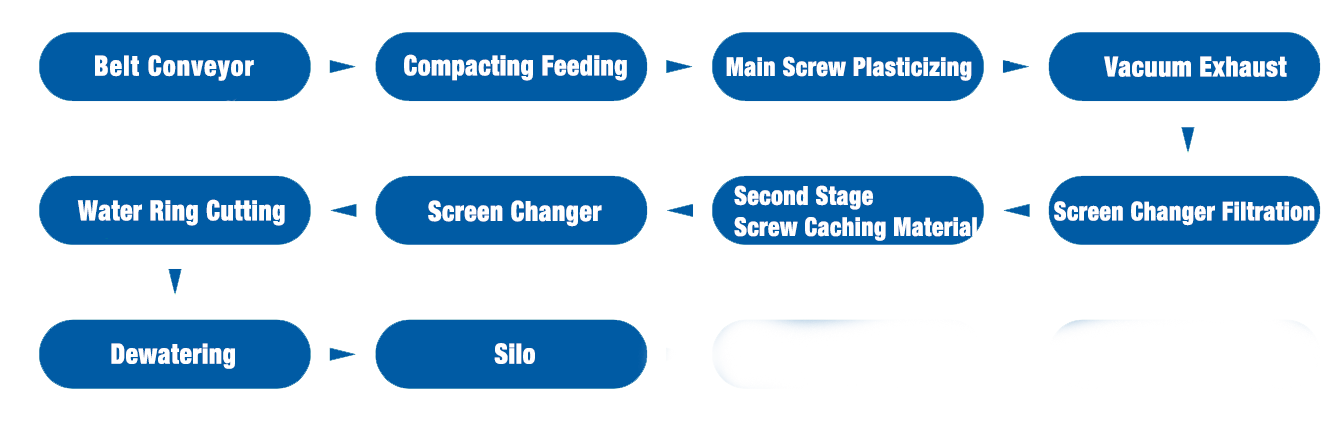

We have a dedicated single screw pelletizing line for soft plastic film . The pelletizing process consists of compacting feeding, main screw plasticizing, screen changer filtration, second stage plasticizing, water-ring pelletizing, dewatering and collection.

Output from 200kg/hr up to 1000kg/hr.

Suitable for specialized plastic recycling plants and pelletizing plants, the equipment has many advantages such as low energy consumption, stable output, easy maintenance, long service life and cost-effectiveness.

Output from 200kg/hr up to 1000kg/hr.

Suitable for specialized plastic recycling plants and pelletizing plants, the equipment has many advantages such as low energy consumption, stable output, easy maintenance, long service life and cost-effectiveness.

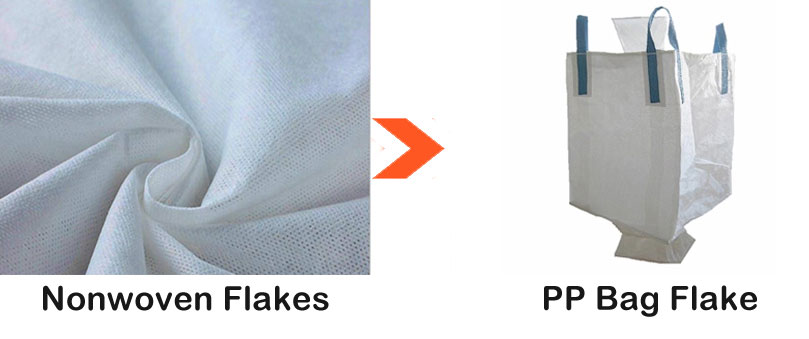

Materials available for processing

Parameter overview

| Machine Model | Agglomerator | Single Screw Extruder | Capacity(kg/h) | |||

| Effective Volume(L) | Motor(KW) | Screw Diameter(mm) | L/D Ratio | Motor(kw) | ||

| ML85-100 | 300 | 37-45 | 85 | 28-33:1 | 55-75 | 180-260 |

| 100 | 10:1 | |||||

| ML100-120 | 500 | 55-75 | 100 | 28-33:1 | 90-110 | 260-350 |

| 120 | 10:1 | |||||

| ML130-150 | 800 | 90-110 | 130 | 28-33:1 | 132-160 | 450-550 |

| 150 | 10-12:1 | |||||

| ML150-160 | 950 | 110-132 | 150 | 28-33:1 | 185-200 | 650-750 |

| 160 | 12:1 | |||||

| ML160-180 | 1100 | 110-132 | 160 | 28-33:1 | 220-250 | 800-1000 |

| 180 | 12:1 | |||||

| ML180-200 | 1100 | 160-185 | 180 | 28-33:1 | 280-316 | 900-1200 |

| 200 | 12:1 | |||||

Brief description of cleaning process

Cleaning line detail photo set

Turnkey Project Delivery Case

- Material: From LDPE film into pellets

- Output Capacity: 800-1000KG/H

- ScrewDiameter: 160/180Φ

- Installation Power:220-250KW

- Pelleting Method: Water-ring cutting

GANGSU provides operation manual (English version) to instruct how to maintain and install and operate the machine, if any technical problem, the buyer can communicate with the seller by phone call and email.

During warranty period, the seller will change spare parts (except for wearing parts like: blades, heating parts and small electrics etc.) for the buyer when parts worn-out free of charge. GANGSU will deliver the needed parts to you.

Request A Free Quote

We'd Like To Work With You

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

- Contact Person:Marco Gu

- Tel:+86 189 6221 0868

- Whatsapp:+86 189 6221 0868

- Email:[email protected]

- No 17, TongDe Rd, Leyu Town, Zhang Jiagang City, JiangSu Province, China